Email: info1@peroxide.cn

Аddress: 3808 Zhencheng Road , Jiangyin city, Jiangsu Province, China

Zip code: 214400

2023-12-06 2:05:33 greenrox

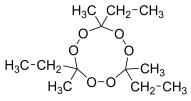

Greenrox™ 301-20PP stands as an effective peroxide formula tailored specifically for the controlled production of rheological polypropylene (CR-PP) within the 200-250°C extrusion range. Its bead-shaped masterbatch, derived from liquid Trigonox® 301-20PP, facilitates a precise and meticulous peroxide dosage into the polymer. This formulation ensures a more uniform peroxide distribution throughout the polymer, offering distinct advantages.

The use of bead-shaped formulation, as opposed to the liquid form, notably enhances control over the visbreaking process.Greenrox™ 301-20PP empowers polypropylene manufacturers with remarkable flexibility in manipulating a polymer’s Melt Flow Index (MFI). Even minor alterations in peroxide concentration or process temperature can yield significantly varied MFIs.

In industrial realms like plastic manufacturing and rubber processing, Greenrox™ 301-20PP serves as a trusted solution, enabling producers to fine-tune and optimize product performance through its nuanced control capabilities.

First, our products have significant advantages in temperature range and extrusion process. In contrast to TRIGONOX 301-20PP, our formulation is specifically designed for extrusion processes in the temperature range 200-250°C. This focus on polymer production under specific temperature conditions makes our products more stable and efficient.

Secondly, we use a liquid formula in bead form, which is superior in addition and distribution compared to traditional liquid forms. This bead format ensures a more precise and even distribution of peroxide within the polymer, improving product quality and performance.

In addition to this, another significant advantage of our products is the control of the visbreaking process. Compared to TRIGONOX 301-20PP, our formulation provides better control over this critical process, ensuring a smoother and more stable polymer production process.

Finally, the flexibility of our products is also worth mentioning. Greenrox™ 301-20PP gives polymer producers such flexibility in controlling the melt flow index (MFI) of the polymer that even small changes in peroxide concentration or process temperature can have a significant impact. This flexibility gives manufacturers more room to control and adjust product performance to meet a wider range of application needs.

To sum up, our product has competitive advantages over TRIGONOX 301-20PP in terms of accuracy, process control and flexibility. Greenrox™ 301-20PP can not only benchmark competitors’ products, but also demonstrate superior performance and innovation in specific application areas, bringing more efficient and reliable solutions to the polymer manufacturing industry.

In addition, our Greenrox™ 301-20PP has a more favorable price than TRIGONOX 301-20PP! Welcome to contact us to order.